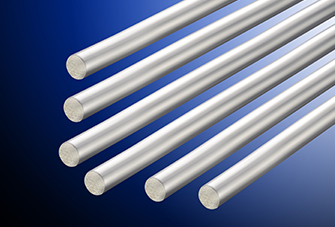

aluminium ec rods

Our Aluminium EC (Electrical Conductor) Grade Rods are one of the preferred types in electrical industries. Owing to excellent characteristics of our aluminium, they are predominantly used in overhead power transmission and distribution cables.

With purity of 99.5% aluminium (minimum), our Aluminium EC Grade Rod is the preferred choice and alternative to copper due to its high conductivity, lightweight characteristic, excellent form, corrosion resistance and superb malleability to fit a wide range of processing.

A detailed specification of our Aluminium EC Grade Rod is as follows:

| MECHANICAL AND ELECTRICAL PROPERTIES | ||||

|---|---|---|---|---|

| Designation | Tensile Strength |

Conductivity at 20°C (Minimum) |

Volume Resistivity at 20°C (Maximum) |

Product Specification |

| MPa | %IACS | Ohm.mm2/m | ||

| 1350-O | 59 - 97 | 61.8 | 0.027899 |

|

| 1350-H12 | 83 - 117 | 61.5 | 0.028035 |

|

| 1350-H14 | 103 - 138 | 61.4 | 0.028080 | |

| 1350-H16 | 117 - 150 | 61.3 | 0.028126 |

|

| 1370-H12 | 83 - 117 | 61.5 | 0.028035 |

|

| 1370-H14 | 103 - 138 | 61.4 | 0.028080 | |

| 1370-H14 (HC) | 108 - 127 | 62.0 | 0.027808 |

*HC = High Conductivity Upon request |

| APPLICATION AND ADVANTAGES | ||

|---|---|---|

| Type | Application | Advantages |

|

Aluminium Aluminium |

Widely used for electrical conductor as wire and solid shaped conductor Widely used in the production of electrical conductor for magnetic motor With it's purity of 99.7% of aluminium (higher than others), makes this conductor has higher conductivity with softer rod |

Conductivity In excess of twice that of copper by unit weight Light Weight Due to its proven light weight and excellent bend qualities make our EC Aluminium favorable for further customization Workability Permitting a wide range of processing from wire drawing to extrusion or rolling. Excellent bend quality. Aluinium possesses high elongation that eases the cold work process Corrosion Resistance A tough, protective oxide coating quickly forms on freshly exposed aluminium and it does not thicken significantly from continued exposure to air Creep Like all metal under sustained stress, there is a gradual deformation over a term of years. With aluminium, design factors take it into account Compatibility with Insulation Does not adhere to or combine with usual insulating materials. No tin-coating required; clean stripping |